The cleanliness of medical instruments is a crucial part of providing high-quality patient care. Suomen Välinehuolto Oy ensures that healthcare instruments are expertly and reliably serviced, while Kiilto’s cleaning and disinfection solutions guarantee results that meet the highest standards.

Suomen Välinehuolto Oy is the only private company in Finland dedicated solely to providing instrument maintenance services. Its clients include laboratories, medical centres, dental care units, and operating theatres that either lack their own instrument maintenance facilities or require additional capacity. Suomen Välinehuolto operates in Helsinki, Tampere, and Kaarina.

“Our service operates on a turnkey basis to make instrument maintenance as effortless as possible. Clients deliver their instruments to Suomen Välinehuolto, and we take care of the cleaning,” explains Taru Mattila, the CEO of Suomen Välinehuolto.

The instruments are typically sterilised using steam, but prior to sterilisation, they are meticulously cleaned and disinfected. Suomen Välinehuolto relies on Kiilto’s products throughout all pre-sterilisation stages, as their hygiene solutions for instrument care are both reliable and effective.

“Instrument reprocessing is often an invisible aspect of patient safety, but it is a critical part of healthcare. We are just as responsible for patient safety as doctors and nurses,” notes Ville Kivisalmi, Head of the Helsinki facility at Suomen Välinehuolto.

“People rarely think about the importance of cleaning products. The Kiilto products we use ensure that a high-quality instrument reprocessing is possible, making the instruments safe for use.“

Certified disinfection

Suomen Välinehuolto was founded in 2008, and it has used Kiilto products since the very beginning. Each facility has its own Kiilto representative to ensure smooth cooperation.

“Products designed for healthcare use are an important part of Kiilto’s business and are widely used throughout Finland. For every client, we work together to determine which product best suits their needs. For example, the water quality and the material of the instrument affect the type of detergent we recommend,” describes Heli De Caro-Nummelin, Key Account Manager at Kiilto.

Kiilto and Suomen Välinehuolto strictly comply with the law governing medical devices and supplies. Their operations are guided by the ISO 13485 standard, which applies to quality management systems in the manufacture of medical devices.

Suomen Välinehuolto’s work is always carried out at their own facilities, using cleaning agents specifically designed by the manufacturer for healthcare use. This ensures that the end result precisely meets the required standard.

No compromises on cleanliness in instrument reprocessing

Suomen Välinehuolto is responsible for maintaining all instruments received from its clients. Kiilto’s products are used even before the instruments reach the facility, as Kiilto Pro Hydragel is recommended for pre-treatment.

The first step in the process is to verify the source of the instruments and log them into the system. The actual reprocessing is now almost exclusively done mechanically: the instruments are placed into baskets and racks, which are then loaded into washing and disinfection machines. If manual washing is required, Kiilto Pro Erinox is used.

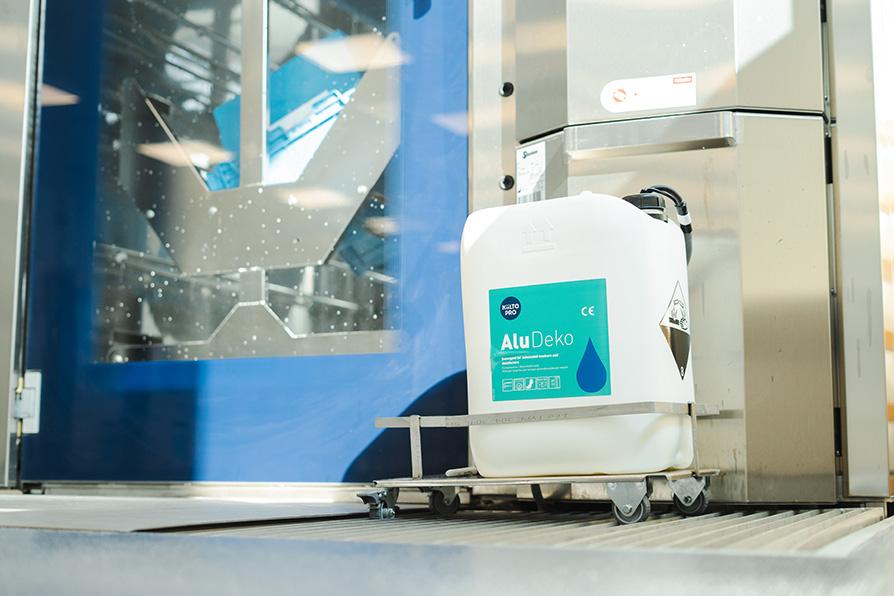

Mechanical washing involves either Kiilto Pro Alu Deko or Kiilto Pro Erizyme, followed by a rinse and heat disinfection. Finally, the instruments are machine-dried and sterilised in an autoclave.

“Thorough cleaning is the only way to ensure that microbes are destroyed during sterilisation. After reprocessing, each instrument is inspected individually by a technician before being returned to the client, ready for use. A well-maintained, high-quality steel instrument can last up to 30 years,” explains Ira Lagus, Production Manager at Suomen Välinehuolto’s Tampere facility.

Product development ensures consistent quality

Many healthcare instruments look the same as they did 100 years ago, but in recent years, there has been significant development in silicone, rubber, and plastic instruments. While older instruments could not withstand high temperatures, almost everything can now be cleaned mechanically and sterilised in an autoclave.

“This directly impacts the quality of maintenance, as machines, under the supervision of skilled technicians, can achieve an unparalleled level of cleaning and disinfection. For us, the ideal scenario is that nothing changes in a functioning process, including the composition of the cleaning agent. That’s why we value the consistent quality of Kiilto’s products,” Ville explains.

“We at Kiilto are truly grateful for all the feedback we receive from the field, including any potential product anomalies identified by customers. Around 10 % of our staff work in product development, and customer feedback helps us ensure our products support patient-safe care and remain consistently high-quality,” adds Heli.

“We’ve noticed at Suomen Välinehuolto that Kiilto responds very quickly to any contact and takes action when necessary. We can always reach out to Kiilto if there’s something to discuss in our cleaning processes,” Taru adds.

Environment and patient safety at the forefront

Kiilto products used in healthcare are primarily manufactured at our factory in Turku, meaning the transport distance to Suomen Välinehuolto’s facilities is very moderate. While there are other options on the market for instrument reprocessing, Kiilto is a domestic choice.

“The short transport distance also supports Kiilto’s Promise to the Environment. Among other things, we’re reducing our indirect CO2 emissions, and our goal is to be carbon-neutral by 2028. We aim for our operations and products to have as little environmental impact as possible,” Heli explains.

Suomen Välinehuolto also incorporates environmental considerations into its processes.

“We don’t use any cleaning or disinfection products unnecessarily. Dosing is always based on actual need. We use the products thoughtfully yet sufficiently to ensure one wash cycle is enough to clean the instruments,” Ville notes.

Suomen Välinehuolto considers the environmental impact of its processes by using cleaning and disinfection agents thoughtfully, yet sufficiently.

Suomen Välinehuolto also avoids using disinfection products with harmful properties if a milder, broad-spectrum product suffices. The goal is always to find the balance between ensuring patient safety and using chemicals in the appropriate dosage.

“Kiilto’s expertise also helps us with this, as they’re great to collaborate with when it comes to improving processes. Kiilto is not just a supplier that delivers cleaning agents; they have a deep understanding of the needs of instrument reprocessing,” Taru emphasises.